- Panoramica

- Product Description

- Product Parameters

- Technical Advantage

- Detailed Photos

- FAQ

Informazioni di Base.

Descrizione del Prodotto

10Ton Black Engine Oil Distillation Recycling Machine Used Oil Purification Plant

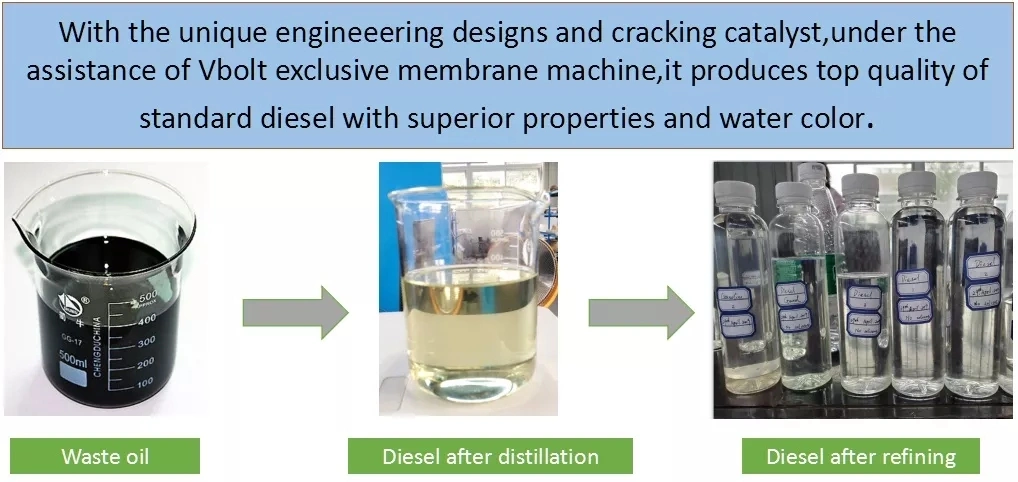

waste oil recycling machine can process waste engine oil, used motor oil, black oil, tire oil, plastic oil to clean diesel. This kind of diesel can be used to tractors, trucks, diesel oil generator, power generator etc. Oil recovery average rate: 85%-95%. Unique design and outstanding functions can help customer create more profit. This equipment is matched with pyrolysis plant. It is widely applied in waste oil management industry.

The raw material for waste oil recycling machine

1) crude oil of Waste plastics ,waste rubber refining

2) Waste oil such as: waste diesel engine oil, waste oil, waste slag, etc

3) waste crude oil

4) Waste wash a oil

The final product after distillation

| No. | End Production | Yield | Usage |

| 1 | Diesel | 73% | Used for diesel engine |

| 2 | Gasoline | 12% | Used for gasoline engine |

| 3 | Residue Oil | 9% | * Feeding into Pyrolysis Machine for second Pyrolysis * Sold directly for building road |

| 4 | Non-Condensible Gas | 3% | Recycle as Heating fuel after treated by Gas-treatment System |

| 5 | Other | 3% | * Water and impurity 2% * Loss 1% |

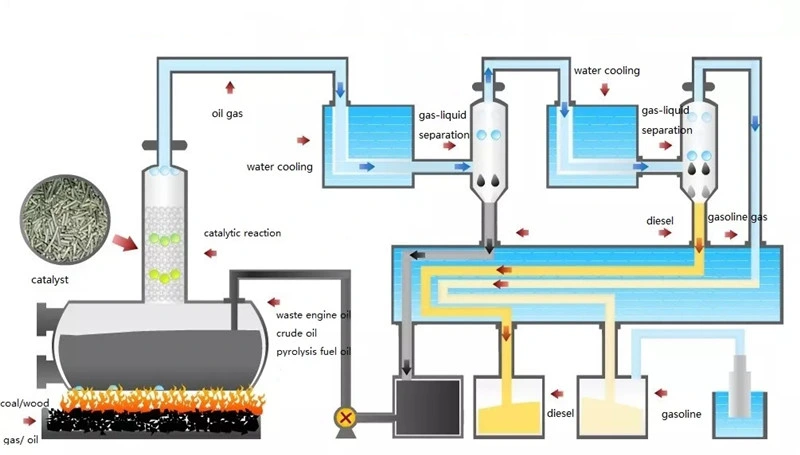

Working Process of Waste Oil Distillation Machine 1. Heat the heat conduction oil with the heat conduction oil furnace;

1. Heat the heat conduction oil with the heat conduction oil furnace;

2. The heat conducting oil flows into the coil in the distillation reactor and heats the waste engine oil in the distillation reactor;

3. When the waste engine oil is heated to a certain temperature, the reactor is directly heated with fuel. As the temperature increases, the waste engine oil produces oil and flows into the buffer tank. The odorous light components in the waste engine oil can be distilled and collected into the distillation tank.

4. The oil gas from the buffer tank enters the catalytic tower. In the catalytic tower the macromolecular oil gas are broken down into smaller molecules .

5. Oil gas of small molecules enter the cooling system through the catalytic tower and are cooled into liquid oil;

6. After the oil gas steam out, the distillation reactor memory has plenty of hot asphalt, which can be extracted by the asphalt pump.

| SPECIFICATIONS FOR USED ENGING OIL RECYCLING MACHINE | |||

| Capacity | 5TPD, 10TPD, 20TPD, 30TPD...300TPD | ||

| Working Type | Continuous Working, Semi-Continuous Working | ||

| Automatic Degree | Fully Automatic, Semi-Automatic | ||

| Applicable Material | Crude Oil, Used Engine Oil, Waste Hydraulic Oil, Plastic Oil, Tyre Oil, Mixed Waste Oil, Other waste oil as customer required | ||

| Heating Fuel | Fuel Oil, Natural Gas, Electric, Coal, Firewood | ||

| Main Parts Material | Q345R Steel Plate, Alloy Steel Plate, Stainless Steel | ||

| Machine Covering Area | Varies by Design and Capacity | ||

| Technology Adopted | Catalytic Pyrolysis Distillation, Refined Filtration, Self-made Gaseous and Liquid Catalyst,etc... | ||

Reactor

1. Made by Q245R boiler plate. Also can choose SS310, 310S+Q345R

2. Auto-welding both inside and outside

3. With rock wool insulation board

Catalyst chamber

1. Improve oil yield and oil quality

2. Reduce the speed of oil gas so that it can be better cooled

Oil-water separator

1. Separate oil and water

2. Collect heavy oil

Condenser

1. The oil gas is cooled separately by small pipes inside condenser

2. Light oil is collected here

Vacuum device

Keep machine running under normal pressure

Anti-back fire device

1. Recycle residual gas to furnace as fuel

2. Water sealing design prevent tempering

Dust removal device

Dispose of flue gas caused by using coal, wood, oil or natural gas

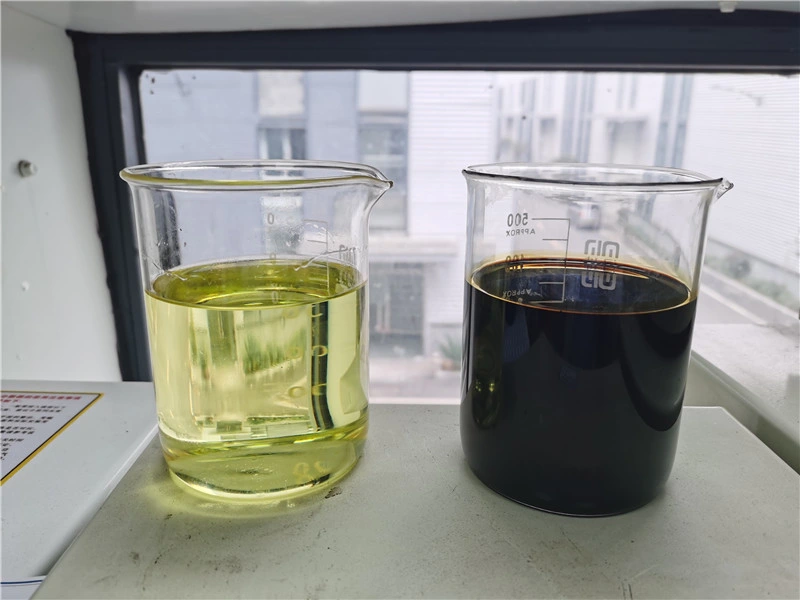

Final Diesel Oil Report After Distination

| Project | Diesel | Standard |

| Oxidation stability | 2.2 | ≤2.5mg/100ml |

| Sulfur content(%) | 0.3 | M/m ≤0.2 |

| 10% steamed residual carbon residue (%) | 0.33 | M/m ≤0.3 |

| Ash content (%) | 0.16 | %M/m ≤0.01 |

| Water content (%) | traces | / |

| Mechanical impurities | / | / |

| Density (G/ML) | 0.85 | 0.83-0.87 |

| Solidifying point(ºC) | -10 | 0 |

| Flash point (closed )(ºC) | 45 | 55 |

| Movement viscosity | 3.5 | (20ºC ) mm2/s 3.0-8.0 |

| Combustion value(Kcal) | 9500 | 8500 |

| Colority | 1.2 | ≤3.5 |

| Cetane number | 40 | 45 |

| Acidity | / | Mgkoh/100ml≤7 |

Q: What is the yield of this Waste Oil Recycling To Diesel Plant?

A: Typically the yield of our Waste Tire Pyrolysis Oil Distillation plant is between 85-90% (depending on variations of water content, light HC and others ingredients from waste oil.)

Q: How many areas are required to build the Waste Tire Pyrolysis Oil Distillation plant?

A: The land area required usually depends on the capacity of your plant. We can calculate the area needed and give you the plant designs.

Q: What is the warranty of the Waste Engine Oil Distillation plant?

A: 12 months free guarantee and life long standard paid service.

Q: Can you install the production line and train our stuffs?

A: Yes we can. We'll send engineers to help you install the used motor Oil Distillation plant and train your workers until the machine is skillfully operated.

Q: What is the operation cost of this Waste Tire Oil Distillation plant?

A: Please consult one of our sales representative for more information about operation cost and turnover of capacity you are interested. We will be providing you the professional budgets breakdown for your particular project.